Plating Excellence, Cost Efficiency

- ABOUT US

- Core Technology

- Automatic Production Line

- Centrifugal Plating Line

- Horizontal Plating Equipment

- Peripheral Equipment

- …

- ABOUT US

- Core Technology

- Automatic Production Line

- Centrifugal Plating Line

- Horizontal Plating Equipment

- Peripheral Equipment

Plating Excellence, Cost Efficiency

- ABOUT US

- Core Technology

- Automatic Production Line

- Centrifugal Plating Line

- Horizontal Plating Equipment

- Peripheral Equipment

- …

- ABOUT US

- Core Technology

- Automatic Production Line

- Centrifugal Plating Line

- Horizontal Plating Equipment

- Peripheral Equipment

Disk Centrifugal Plating

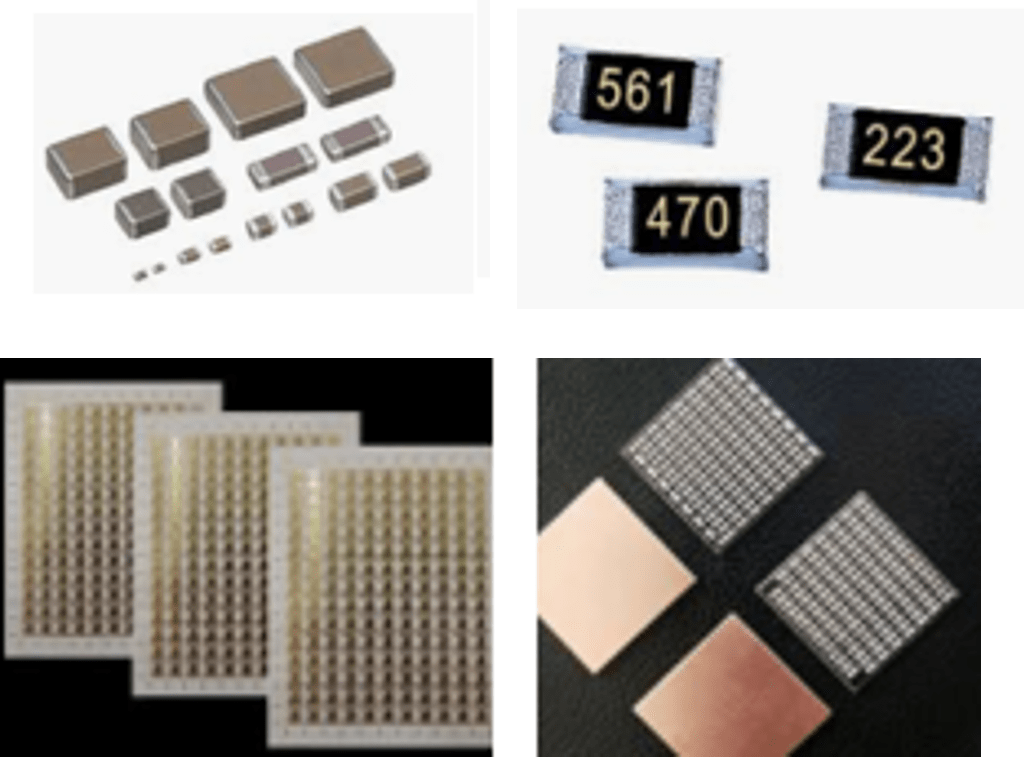

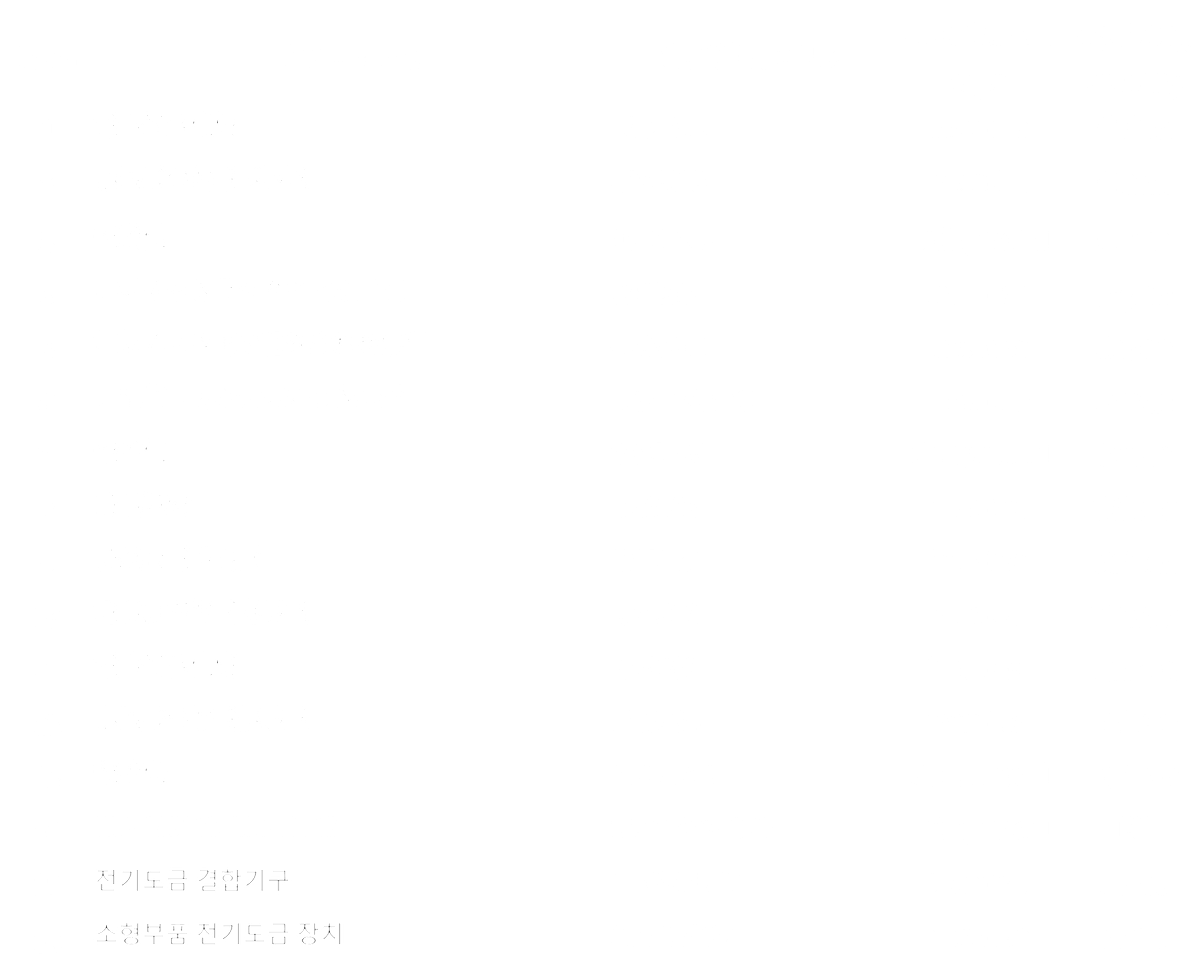

1. Application

- Highprecision, small, sheet, needle, through hole, floating, highrequirement for thickness uniformity, unable to plate using traditional horizontal barrel

method; Disk centrifuge plating barrel is best suit for above applications.

- Highprecision, small, sheet, needle, through hole, floating, highrequirement for thickness uniformity, unable to plate using traditional horizontal barrel

2. Disk Type Plating Machine

Multinational invention patents, excellent application with precisely small parts, outstanding plating distribution, continuous plating, high output.

- Modularized design concept, quick assembly within a week, easy relocation, significantly reduces assemble time and construction.

- Overhead hoist or robotic arm design to improve industrial safety performance.

- Provide main tank utility, consistent plating solution concentration, easy for maintenance and cleaning, and rapid recovery operation.

- Batch drainage after rinse, reduces water usage.

- Intelligence production managing system, flexible production, mass production with consideration of small production diversification.

Hoist Type

Robot Arm Type

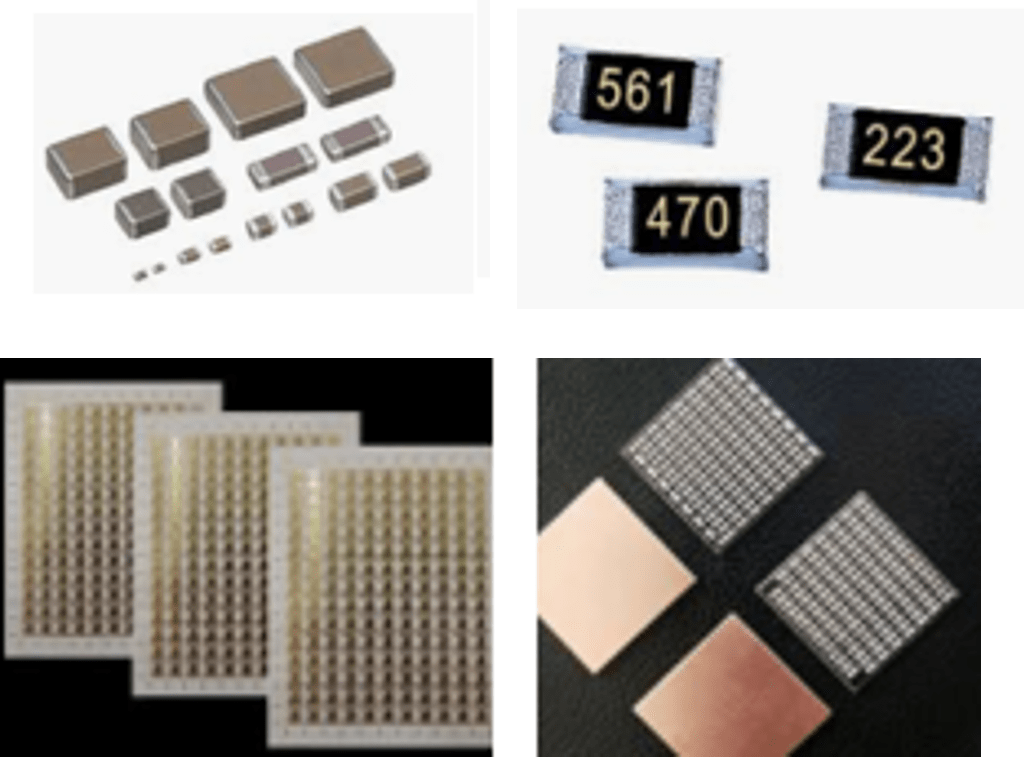

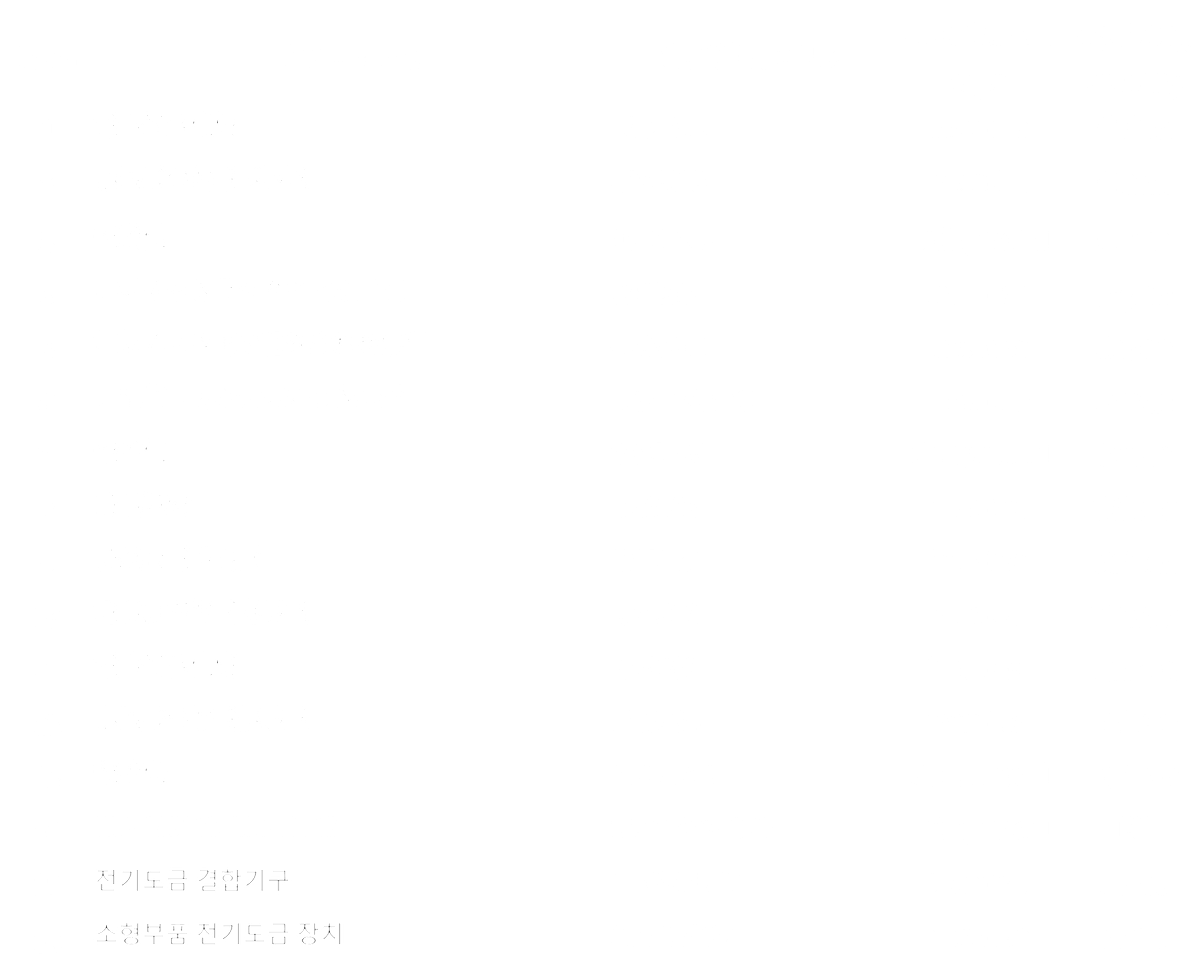

3. Disk Type Rack and Barrel

Multinational invention patent, appliedin extremely small parts, the following explains its coretechnology.

- Plating solution is forced convection, increase solution exchange rate, do not need any conductive media.

- Interchangeable barrel, Shared platinghanger, High uniform film thickness, high productivity.

- Does not need conductive media, saving on anode, reduce plating solution, reduce working procedure.

- Excellent tightness, no risk of product spill or stuck.

- Can configured with RFID to implement intelligent production and maintenance management.

- No material floats issue, increase efficient consistent plating.

Plating Rack

Barrel 1、2、3、4L

4. Effects and Features

- Semi conductive parts or parts requires conductive medium: micro precision, passive component, connectors, testing probes, precise non conductive component.

- Capabilities: Highly uniform thickness, excellent coverage, smoother, lower twinning, water saving, power saving, cathode saving, reduce wastewater, approximate 50% saving operations cost.

- Conductive parts or parts do not requires conductive medium: connectors, test probes, conductive metals

Capabilities: Highly uniform thickness, excellent coverage, smoother.

Semi conductive

Conductive

5. Technical Services

- Globally pioneered equipment, international patent invention, Hallmark proudly to share and explore together in terms of hardware, software, parameter with our business partners.

6. Tsinghua University(NTHU) Analysis Report

- Department:TsingHua University Material Department Duh Jeng-Gong Laboratory

- Sample:MLCC Capacitance

- Complete Date:March 09, 2020

Ni Disk Plating Sn

Ni Conventional Plating Sn

Analysis Scope: Top and Corner

Quality: Excellent coverage, Smoother, Uniform Thickness

Disk Plating

Conventional Plating

7. Existing customers

Contact us

TEL. +886-7-352-6969

FAX. +886-7-352-2323

E-Mail:

Subscribe to our latest news

All rights reserved© 2024

HALLMARK TECHNOLOGY CO., LTD.